I have brought a new piece of Banyan bark, this time only just beaten to become flexible enough to wrap it around the magic frame. Like the previous piece, as soon as I wrap the bark around the metal, the blackening process begins. I love that magic!

I have also wrapped a piece of eucalyptus-dyed gauze on the outside, part of which just sits on the metal, the other part covering the tapa. I want to find out, whether the area that covers the tapa will be dyed a different colour, i.e. whether the tapa’s own ‘juice’ leaves a trace.

I have also wrapped a piece of eucalyptus-dyed gauze on the outside, part of which just sits on the metal, the other part covering the tapa. I want to find out, whether the area that covers the tapa will be dyed a different colour, i.e. whether the tapa’s own ‘juice’ leaves a trace.

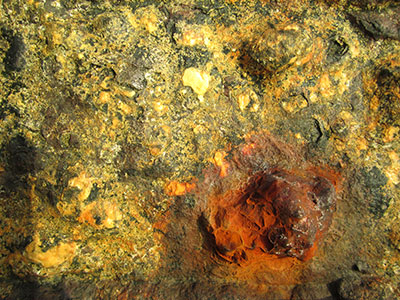

The weather is not so wonderful and I’m in a hurry, so I just drive to the beach and bring the frame back to unwrap at home. What I find is quite photogenic.

The weather is not so wonderful and I’m in a hurry, so I just drive to the beach and bring the frame back to unwrap at home. What I find is quite photogenic.

Yes, the tapa has added some brown colour to my gauze. Where it has just touched the metal it is only a mottled gray.

Yes, the tapa has added some brown colour to my gauze. Where it has just touched the metal it is only a mottled gray.

The dried bark keeps its shape as I carefully peel it off the frame. I should leave it as is and use it as a sculptural piece…

The dried bark keeps its shape as I carefully peel it off the frame. I should leave it as is and use it as a sculptural piece…

However, my intention is to soak the dried bark and beat it until it is as thin as possible. I’m glad we live way outside the village, because it is a Sunday morning when I sit down to do that. I just hope the lovely sound of my tutunga (wooden anvil) will not be heard in church…

However, my intention is to soak the dried bark and beat it until it is as thin as possible. I’m glad we live way outside the village, because it is a Sunday morning when I sit down to do that. I just hope the lovely sound of my tutunga (wooden anvil) will not be heard in church…

I fold the strip lengthwise and beat it, beat it, beat it, unfold and refold it and keep beating some more until I run the risk of ripping it with the next beats. Only then am I satisfied.

I fold the strip lengthwise and beat it, beat it, beat it, unfold and refold it and keep beating some more until I run the risk of ripping it with the next beats. Only then am I satisfied.

In its wet state, the tapa’s colours are rich; they will fade a bit as the bark dries.

In its wet state, the tapa’s colours are rich; they will fade a bit as the bark dries.

The material is thin and see through. One can clearly see the marks the ridges of the ike (beater) have left behind. I had hoped that I could perhaps beat tapa and gauze together, but that hasn’t worked out. I feel tempted now to experiment some more with gauze…

The material is thin and see through. One can clearly see the marks the ridges of the ike (beater) have left behind. I had hoped that I could perhaps beat tapa and gauze together, but that hasn’t worked out. I feel tempted now to experiment some more with gauze…